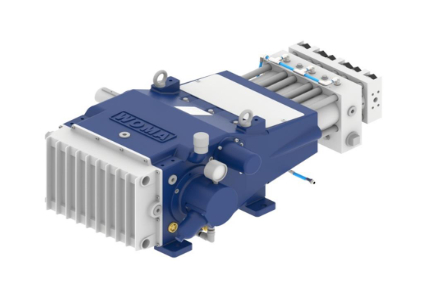

High-pressure pump 1000M

The type 1000 M high-pressure pump provides a max. operating pressure of 3,000 bar and a max. flow rate of 218 l/min. It is ideal for work such as cutting, fragmenting, stripping and de-rusting.

The type 1000 M high-pressure pump provides a max. operating pressure of 3,000 bar and a max. flow rate of 218 l/min. It is ideal for work such as cutting, fragmenting, stripping and de-rusting.

The type 550 M high-pressure pump provides a max. operating pressure of 3,000 bar and a max. flow rate of 105 l/min. Plunger pump is ideal for work such as cutting, fragmenting, stripping and de-rusting.

The type 400 M high-pressure pump provides a max. operating pressure of 3,000 bar and a max. flow rate of 67 l/min. Water pump is ideal for work such as cutting, fragmenting, stripping and de-rusting.

The type 330 M high-pressure pump provides a max. operating pressure of 3,000 bar and a max. flow rate of 56 l/min. Plunger pump is ideal for work such as cutting, fragmenting, stripping and de-rusting.

The type 250M high-pressure pump provides a max. operating pressure of 3,000 bar and a max. flow rate of 40 l/min. It is using for work such as cutting, fragmenting, stripping and de-rusting.

The type 190M high-pressure pump provides a max. operating pressure of 3,000 bar and a max. flow rate of 34 l/min. Plunger pump is ideal for work such as cutting, fragmenting, stripping and de-rusting.

High-pressure pump 150M provides a max. operating pressure of 3,000 bar and a max. flow rate of 34 l/min. These plunger pumps have high volumetric efficiencies even at high-pressures. Plunger pump is ideal for work such as cutting, fragmenting, stripping and de-rusting.

The type 70M high-pressure pump provides a max. operating pressure of 3,000 bar and a max. flow rate of 9.8 l/min. Ideal for work such as cutting, fragmenting, stripping and de-rusting.

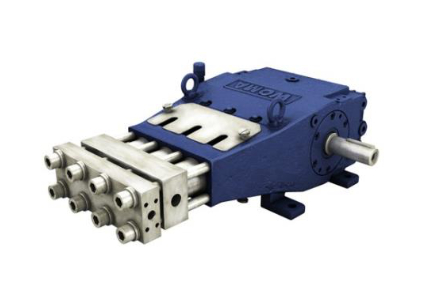

M-pump series

WOMA M Series high-pressure pumps are ideal for applications such as cutting, disassembling, removing coatings, and rusting.

This type of plunger pump has a central valve design and has high volumetric efficiency even at high pressures. The carbide plungers used are very robust and provide long service life and low maintenance costs. Type M pumps are not sensitive to sudden temperature fluctuations. The plunger guide ensures a long service life of the seal system, and the water seal system used prevents leakage, ensures longer high-pressure seal life, and prevents air infiltration.

On request, the availability of an ATEX version can be checked.